Feasibility study report on industrialization and development of 100-ton Eucommia gum biomedical functional materials

Scarcity of natural rubber resources and oversupply have seriously constrained the development of China's rubber industry. The development of the second natural rubber resources - eucommia rubber is one of the most positive and effective ways to supplement the natural rubber resources, but also to accelerate the healthy development of China's rubber industry is a fundamental measure.

Scarcity of natural rubber resources and oversupply have seriously constrained the development of China's rubber industry. The development of the second natural rubber resources - eucommia rubber is one of the most positive and effective ways to supplement the natural rubber resources, but also to accelerate the healthy development of China's rubber industry is a fundamental measure.

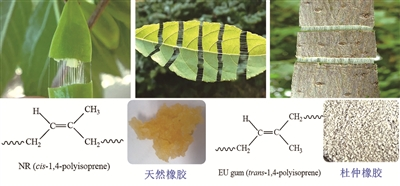

Valuable Industrial Plant Eucommia

Eucommia is a unique plant in China, the planting area of which is several times that of the three-leaf rubber tree, and more than 95% of the world's eucommia resources are in China. Eucommia is highly adaptable and can be planted in 27 provinces from subtropical to temperate zones in China. The improvement of Eucommia's cultivation mode and the progress of Eucommia's seed selection and breeding have laid a very good foundation for Eucommia's resource development.

Eucommia rubber exists in the fruit, leaf, bark and root of Eucommia, in which the leaf contains 2%~5% of rubber, the bark contains 6%~10% of rubber, and the seed and fruit skin contain 12%~18% of rubber. It seems that the content is not high, but the sum of the rubber content of bark, leaves and seeds of fins of each eucommia plant is huge, and the rubber yield of eucommia of a single tree is also higher than that of a single three-leaf rubber tree. The orchardized eucommia forests cultivated with eucommia high-yielding rubber seeds have a fruit yield of 3.5~4.5 tons per hectare, and the rubber yield per hectare can reach 400~600 kg, which is 40~60 times higher than that of the traditional arboriculture mode. The test results of the cultivation mode of eucommia leaf forest show that 3 years after the planting of eucommia leaf forest, each hectare can annually produce 15 tons of eucommia dry leaves, 0.5 tons of eucommia dry skins, 22.5 tons of timber, and the output of eucommia rubber is 500~600 kg per hectare, which lays a good foundation for the large-scale development of natural eucommia rubber.

Duchess tree integrates industrial application, medicine, agro-industry, forest industry, breeding and ecology, and it can develop multiple planting modes as well as three-dimensional planting, which is a valuable industrial plant with great social, economic and ecological benefits. Comprehensive development of eucommia resources can effectively reduce the production cost of eucommia rubber, such as eucommia rubber, eucommia traditional Chinese medicine, eucommia health care products and the development of functional food, eucommia feed additives processing, livestock and poultry breeding, eucommia timber processing, eucommia ecology and soil improvement, eucommia biomass fuel development and utilization, and so on.

Eucommia rubber development climax

Eucommia rubber and natural rubber have the same chemical composition, but the molecular structure is different, isomerism. Duchess rubber has the three major features of double bond, flexibility and trans structure, which can be used as rubber high elasticity materials, low temperature plasticity materials and thermoelastic materials, and is widely used in the rubber industry, aerospace, national defense, shipping, chemical industry, medical care, sports and other areas of the national economy, with a very wide industrial coverage.

As early as in the 1880s, Yan Ruifang, a researcher of Chinese Academy of Sciences, for the first time in the world, used a new vulcanization method to make synthetic dutasteride rubber into elastomers, and processed dutasteride rubber into three types of materials with different uses: thermoplastic functional plastics, thermoelastic shape memory materials and rubber materials, developed a series of patented technologies and a variety of different uses of the functional materials, and for the first time in the world to manufacture the "Duchess rubber/cis rubber blended 3.25-16 motorcycle tire", the tread and sawed cross section are in perfect condition after two years of safe driving.

China's first solvent method eucommia rubber extraction test equipment was built in 1991 in Ruyang, Henan Province. China's first demonstration plant of dulcimer rubber extraction was built in 1996 in Shunyi, Beijing. After that, dulcimer rubber extraction plant was built in Ankang, Shaanxi, Luoyang, Shaanxi and Lingbao, Henan, etc. In 2011, the National Development and Reform Commission, Ministry of Industry and Information Technology, Ministry of Science and Technology and other departments gave support and financial assistance to dulcimer resource cultivation, comprehensive development and dulcimer rubber extraction.

The development and application of China's eucommia rubber has been highly concerned by the United States, Japan and other countries. Under the financial support of Japan's Ministry of Energy and Japan's New Energy and Industrial Technology Comprehensive Development Organization, a research team composed of Japan's Osaka University and Hitachi Zosen Co., Ltd. has persisted in the research of natural eucommia rubber for many years, and successively set up eucommia rubber extracting and production devices in Yangling, Shaanxi Province and Lingbao, Henan Province of China. Osaka University found that a kind of substance named "isopentenyl pyrrolidinic acid" in the leaves of Eucommia dulcis synthesizes Eucommia rubber through the action of four kinds of enzymes, and at the same time, the genes of these enzymes were identified; and another study found that with the increase of Eucommia dulcis isopentenyl pyrophosphate isomerase expression, the content of trans isoprene in Eucommia dulcis plant will be increased by 3~4 times. This is a significant discovery for the significant increase of the trans-isoprene content in Eucommia. This significant discovery has explored an important way to significantly increase the yield of rubber in eucommia. In addition, Japan's Kurary (Kurary) company has built a set of 400 tons / year of synthetic eucommia rubber production unit, the product is mainly used for medical materials market. The United States Goodyear has been synthetic tucumatic rubber used in the commercial manufacturing of high-end tires. In contrast, China's efficient extraction and application of eucommia rubber is still in a weak position.

After decades of efforts, the development of eucommia rubber in China has entered a new stage, and the first set of 100-ton continuous natural eucommia rubber production unit has been put into operation in Xiangxi, Hunan Province, successfully producing natural eucommia fine rubber with purity greater than 94%. The Ministry of Science and Technology launched a national key research and development program project - "new bio-based rubber material preparation technology and application demonstration" in 2017, of which "key technology and performance research on efficient extraction of eucommia rubber One of the important R&D contents is "research on key technology and performance of high-efficiency extraction of eucommia rubber", which aims to build China's first industrialized device for high-efficiency extraction of eucommia rubber with a capacity of 1,000 tons, and in 2019, "Eucommia Resource High-Value Utilization Industry Technology Innovation Alliance" was formally established, which is aimed at promoting the innovation, R&D and transformation of eucommia resource high-value utilization in China. The alliance aims to promote the innovative research and development and achievement transformation of high-value utilization of eucommia resources in China, break through the common and key technology bottlenecks in the development process of eucommia industry, and promote the cooperation and common development of eucommia industry chain, which pushes the development of eucommia rubber, a new type of natural rubber resource, to a new climax.

Wide prospect and huge potential

In recent years, China's research on the application development of eucommia rubber has been gradually active. Eucommia rubber used in high wear-resistant tire rubber can improve the rolling resistance of tires and wear-resistant performance, extend the service life, and achieve fuel savings of about 2.5%. Tests have shown that each ton of eucommia rubber used in tires can save 70 tons of fuel and reduce carbon dioxide emissions by 200 tons.In 2017, Shenyang University of Chemical Technology prepared the world's first bio-based eucommia aviation tires. Eucommia rubber in the aviation and related industries tire development, in line with the international trend of trans rubber-based, the development of long-life, high-strength, safe, energy-saving "green tires", can solve the long plagued by the aviation industry and related industries in the tire strength, tire life, tire friction exothermic a series of major issues, to maximize Reduce the disaster caused by the aircraft tire burst, for China's national defense industry, aerospace industry development provides a new type of rubber materials.

Eucommia rubber is also an excellent modified material for synthetic rubber and plastics. Eucommia rubber can be blended with plastics to produce high-performance plastic alloys, which are widely used in automobile parts, sports equipment, etc., and has a huge potential market in China.

Eucommia rubber can also be used in submarine cables, high-performance v-belts, medical splints, shape memory materials, integrated materials for vibration and noise reduction, and other new functional materials used in special environments.

In addition, the application research and development and promotion of eucommia rubber will play a key role in whether it can drive the rapid development of eucommia large industrial chain. Attaching importance to the R&D of eucommia rubber will promote the product structure and application performance of China's tire and other rubber products industry to a new height. Attaching importance to the strategic position of eucommia rubber, taking the development of eucommia rubber as a leader and realizing the large-scale production of eucommia rubber will realize the comprehensive utilization of eucommia resources in the real sense, thus driving the development of eucommia large industrial chain.

Next

Latest News